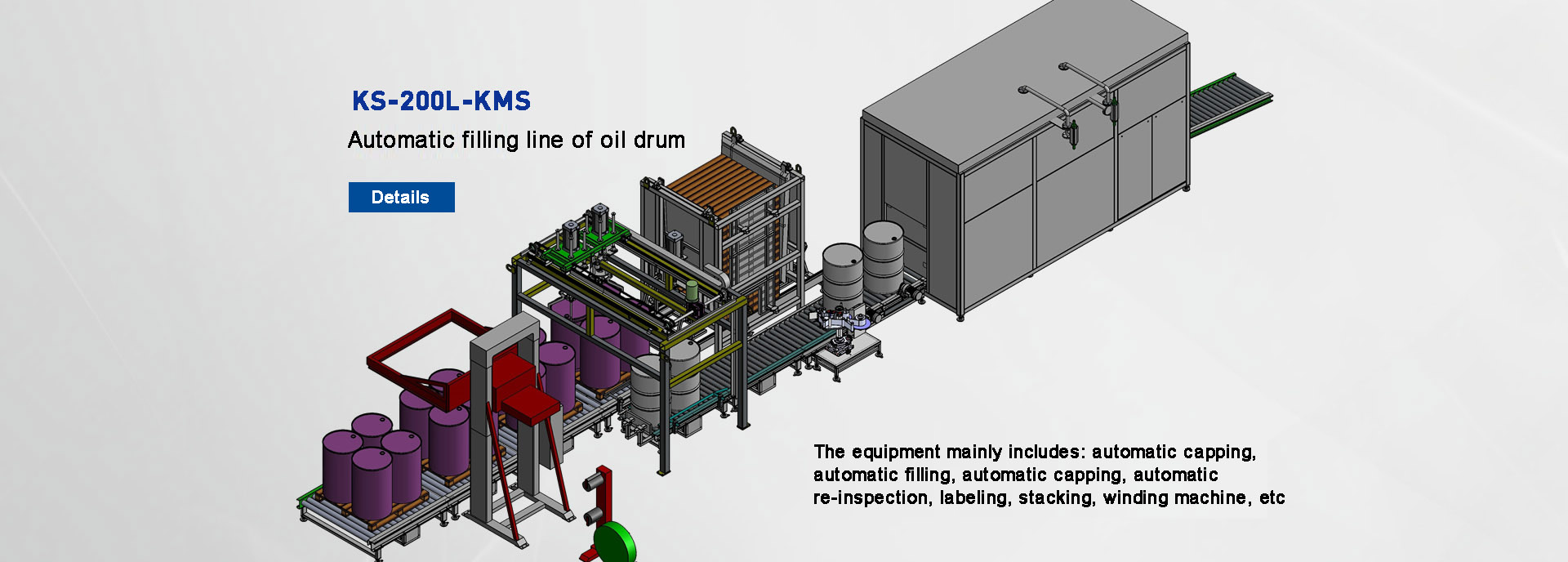

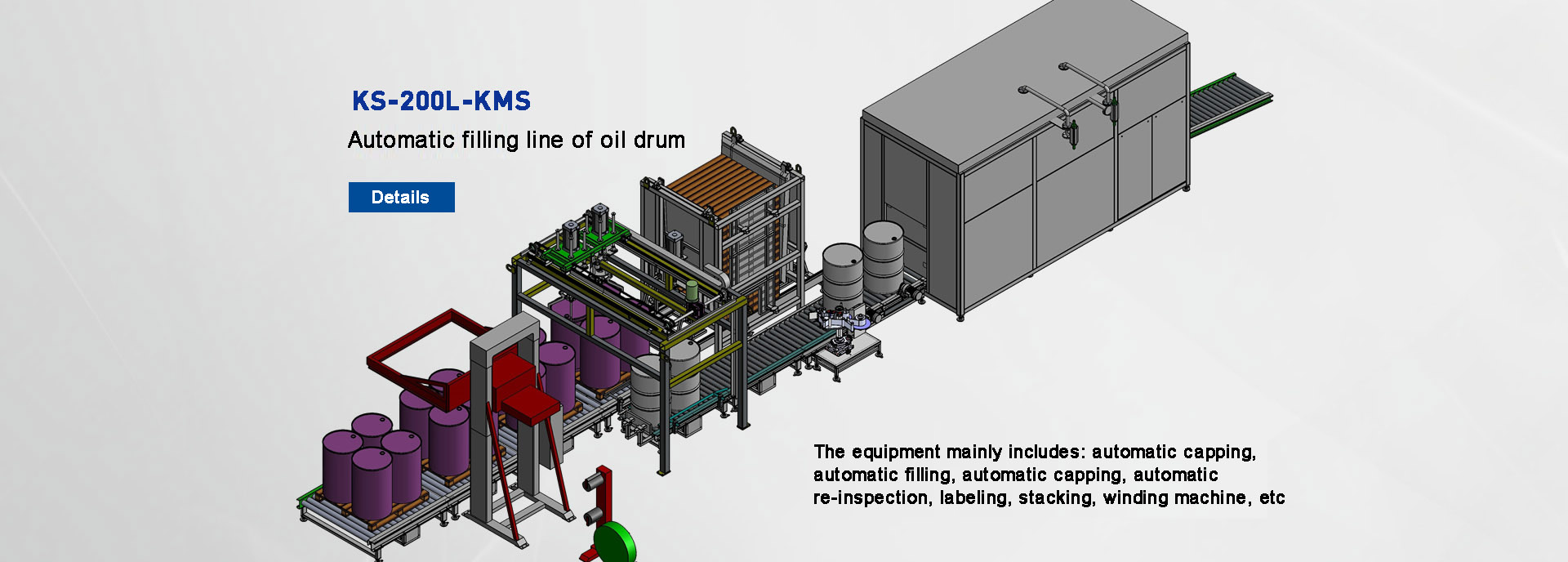

Automatic Explosion-proof Detergent Coating Multifunctional Liquid Filling Machine

Automatic Explosion-Proof Detergent & Coating Multifunctional Liquid Filling Machine

Overview:

The automatic explosion-proof liquid filling machine is designed for safe, precise, and efficient filling of flammable or hazardous liquids such as detergents, coatings, solvents, adhesives, or industrial chemicals. Certified for use in ATEX Zone 1/21 or Zone 2/22 environments, this machine combines high-speed operation, multifunctional versatility, and robust safety features to meet the demands of explosive atmospheres. It is ideal for industries like chemical manufacturing, paint production, pharmaceuticals, or household cleaning products.

Key Features:

Explosion-Proof Design:

ATEX/IECEx Certification: Compliant with Zone 1/21 or Zone 2/22 hazardous area standards.

Spark-Resistant Construction: All electrical components are encapsulated or intrinsically safe.

Static Grounding System: Eliminates static buildup during filling to prevent ignition risks.

Multifunctional Compatibility:

Wide Product Range: Suitable for detergents, coatings, viscous liquids (up to 10,000 cP), and foaming materials.

Adjustable Fill Parameters: Set fill volumes, weights, or rates via touchscreen HMI.

Nitrogen Blanketing (Optional): Inert gas purging to prevent foaming or oxidation.

Precision Filling:

Weight-Based Accuracy: High-precision load cells (±0.1% accuracy) ensure consistent fill levels.

Drip-Free Nozzles: Prevents dripping after filling, reducing mess and cross-contamination.

Anti-Foam Technology: Specialized nozzles minimize air entrapment and foam during filling.

High Throughput:

Fast Cycle Times: Fills up to 60 pails per hour (semi-auto) or 120+ pails per hour (fully auto).

Continuous Operation: Fully automatic models support unattended operation with conveyor systems.

Safety & Compliance:

Emergency Stop Function: Instantly halts operation in case of emergencies.

Overfill Protection: Automatically stops filling if preset limits are exceeded.

Spill Containment: Drip trays or enclosed filling areas catch accidental spills.

User-Friendly Operation:

Touchscreen HMI: Intuitive interface for setting parameters, monitoring batches, and troubleshooting.

Foot Pedal Control: Hands-free start/stop for manual operation.

Quick Changeover: Tool-free nozzle and hose replacement for different container sizes or products.

Customization Options:

Automated Capping: Integrated capping system for sealed containers.

Labeling Integration (Optional): Apply barcodes, batch numbers, or expiration dates.

Heated Jackets (Optional): Maintain optimal temperature for viscous or temperature-sensitive materials.

Maintenance & Cleanliness:

Self-Purging Function: Automatically cleans the nozzle after each cycle.

Tool-Free Cleaning: Quick-disassembly nozzles and hoses for easy maintenance.

IP65/69K Rating: Dust and water resistance for harsh environments.

Versatility:

Container Flexibility: Accommodates various container sizes (e.g., 5L to 20L pails, bottles, or cans).

Viscosity Handling: Efficiently fills thin liquids, thick gels, or pastes.

Multi-Product Support: Program different fill recipes for diverse formulations.

Applications:

Detergents & Cleaning Products: Filling liquid soaps, disinfectants, or cleaners.

Coatings & Paints: Dispensing viscous or thixotropic materials.

Adhesives & Sealants: Filling industrial adhesives or sealants.

Pharmaceuticals: Packaging suspensions, creams, or lotions.

Industrial Chemicals: Handling solvents, oils, or corrosive liquids.

Operation Steps:

Container Loading: Empty container (pail, bottle, or can) is placed on the weighing platform (manually or via conveyor).

Nozzle Positioning: Telescopic nozzle extends into the container to minimize splashing and foam.

Filling: The machine fills the container to the preset weight using load cells.

Foam Control (Optional): Nitrogen blanketing or anti-foam nozzles reduce air entrapment.

Sealing & Capping (Optional): Automated or manual capping applies a sealed lid.

Container Removal: Filled container is removed manually or transferred via conveyor.

Cleanup (Optional): Nozzle self-purges or undergoes manual cleaning.

Benefits:

Safety: ATEX certification, spark-resistant design, and static grounding ensure safe operation in hazardous environments.

Accuracy: Weight-based filling ensures precise dosing, reducing overfilling and material waste.

Speed: High throughput (60–120 containers/hour) improves productivity.

Flexibility: Handles viscous, thixotropic, or foaming liquids with ease.

Ease of Use: Touchscreen HMI and foot pedal control simplify operation.

Low Maintenance: Tool-free cleaning and durable construction minimize downtime.

Customization: Optional features like nitrogen blanketing and automated capping enhance functionality.

Why Choose This Machine?

This automatic explosion-proof liquid filling machine combines safety, precision, and multifunctional versatility into a reliable solution for filling hazardous or flammable liquids. With features like ATEX compliance, weight-based accuracy, and anti-foam nozzles, it addresses the unique challenges of explosive atmospheres while ensuring operator safety and compliance. Its user-friendly design and customization options make it ideal for small to medium-scale production in demanding industries.

Immediate Order:

Website: http://www.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Bottle Liquid Detergent Soap Filling Machine[2025-04-12]

-

Fully Automatic Filling Line for 30L Explosion-Proof Lubricating Oil Solvent[2025-04-07]

-

Automatic Soft Gas Drink Production Filling Line[2025-04-11]

-

Semi-Automatic Desktop Filling Machine for Filling 30L Resin Solvent/Lubricant[2025-04-01]